FUNGSI PENGAWALAN KUALITI

Didalam sesebuah sistem pengeluaran barangan mahupun penyampaian perkhidmatan variasi pada hasilnya boleh berlaku disebabkan oleh:

- Variasi rambang semulajadi (chance)

- Kegagalan menepati spesifikasi

Pengawalan merupakan proses menentukan agar sesebuah organisasi melangsungkan fungsinya mengikut objektif dan perancangan.

Perancangan serta pengawalan bertindakbalas dan bergandingan untuk menentukan kualiti hasil. Juran mentakrifkan Pengawalan Kualiti sebagai “…proses kawalan yang merangkumi aktiviti mengukur kualiti sebenar yang dicapai, membandingkannya dengan standad dan mengambil tindakan keatas perbezaannya (Juran). Tugas utama pengawalan ialah mengekalkan kualiti. Jelas dari perbincangan sebelum ini, bahawa pengukuran dan pengawalan kualiti perlu dilakukan pada setiap peringkat proses pengeluaran atau pemberian perkhidmatan, ia-itu:

- Pengawalan Kualiti Rekabentuk (produk, proses, sistem)

- Pengawalan Kualiti Input (pekerja, mesin, bahan, fasiliti, persekitaran)

- Pengawalan Kualiti Proses

- Pengawalan Kualiti Output (barangan / perkhidmatan)

Perhubungan antara Pengukuran, Standad dan Pengawalan

Ciri kualiti sesuatu produk atau proses adalah nilai nilai yang ada padanya yang menentukan samaada produk atau proses itu dianggap sebagai berkualiti atau tidak. Ciri ciri atau nilai nilai ini pada asalnya kerapkali bersifat subjektif dan sukar untuk diukur.

Khidmat kesihatan merangkumi penyampaian khidmat serta juga pemberian barangan (contohnya ubat, darah, makanan dsb). Kualiti perkhidmatan bukan sahaja dinilai dari hasil rawatan tetapi dalam banyak keadaan pemilihan bahan, kaedah serta masa yang dipilih untuk melakukan sesuatu proses juga penting. Justeru itu, jika kualiti ingin diukur takrif kualiti itu sendiri perlu diterjemahkan kepada sesuatu yang lebih jelas.

Kualiti boleh ditakrifkan sebagai:

- Memuaskan kehendak pelangan

- Menepati tujuan kegunaan sesuatu produk (boleh digunakan)

- Memenuhi keperluan

Definasi seperti diatas membolehkan ciri ciri kualiti diberi ukuran yang berskala. Tahap tertentu sukatan ciri ciri tersebut yang boleh diterima menjadi standad dan spesifikasi sesuatu produk. Standad perlulah ditetapkan semasa produk tersebut direkabentuk.

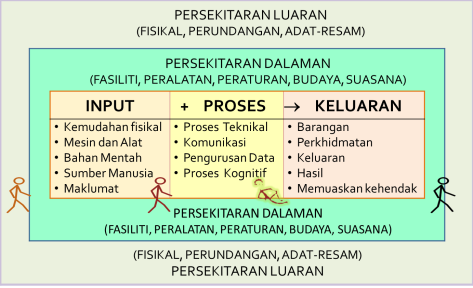

Unsur unsur yang membolehkan pencapaian kualiti adalah bahan bahan input, proses, sistem dan persekitaran yang sesuai. Kebanyakan unsur unsur ini boleh diukur atau disukat mengikut bilangan, masa, ukuran fisikal lain ataupun kos. Sesetengah unsur bersifat subjektif. Kemahiran dan sifat pekerja dan juga suasana budaya merupakan unsur yang agak sukar diukur. Kesemua unsur unsur ini perlu ditetapkan standadnya.

Fungsi Pengukuran dan Hubungannya dengan Fungsi Pengawalan

Untuk mengetahui samada kualiti telah tercapai tahapnya perlu diukur. Cabaranya ialah menentukan apa yang hendak diukur dan cara pengukurannya

Unsur unsur yang menentukan kualiti sesebuah produk atau perkhidmatan boleh dikenalpasti jika Teori Sistem Pengurusan Operasi difahami dengan jelas. (refer to article)

MENGUKUR KUALITI PERKHIDMATAN

Kualiti perkhidmatan agak susah hendak diukur berbanding dengan kualiti baranagan. Beberapa perkara perlu diambilkira untuk mengukur kualiti perkhidmatan iaitu:

- Penjelasan tentang maksud kualiti

- Menegenalpasti parameter (ciri kualiti) yang hendak diukur

- Penggunaan alat pengukur, skel dan unit ukuran

- Penetapan standad (had yang boleh diterima / had kawalan)

Definasi Kualiti Perkhidmatan

Ada tiga pendekatan bagaimana kualiti ditakrifkan iaitu:

- Memuaskan keperluan pelanggan

- Boleh diguna atau dipakai (gunapakai)

- Menepati standad atau spesifikasi

Takrif takrif ini hanyalah tiga cara membayangkan kualit dari tiga sudut berlainan. Dari sudut pengawalan, penggunaan setiap istilah tersebut bergantung kepada peringkat mana ia hendak dipakai. Takrif pertama diguna pakai ketika menilai kesan keseluruhan yang dialami oleh pengguna. Takrif kedua merujuk secara khusus kepada ciri boleh guna iatu ciri utama kualiti sebarang baranagan atau perkhidmatan. Dalam khidmat penjagaan kesihatan ia bermaksud keberkesanan (memberi faedah atau manfaat). Takrif ketiga memeberi penekanan kepada penyediaan input, proses dan persekitaran yang membolehkan pencapaian hasil yang diigini.

Dimensi Kualiti

Walaupun keberkesanan merupakan ciri utama sesuatu perkhidmatan, namun untuk memenuhi kehendak pelanggan, banyak lagi ciri kualiti (dimensi) perlu diberi perhatian. Pengawalan kualiti perlu dikenakan bukan sahaja kepada hasilnya tetapi juga terhadap proses, input dan juga persekitaran. Ciri yang perlu diukur, cara mengukurnya dan standad yang hendak dibuat perbandingan perlu ditentukan bagi setiap aspek. Juag pemilihan ciri yang ingin dititikberatkan bergantung kepada keperluan, tujuan, dan objektif yang hendak dicapai.

Penggunaan kawalan kualiti perlu pada dua peringkat:

- Peringkat Merekabentuk Sistem Pemeberian Khidmat – digunapakai keatas kumpulan sasaran (pelanggan) secara umum

- Peringkat Operasi – digunapakai keatas setiap pelanggan dan setiap ketika khidmat diberi

Untuk menegtahui pencapaian keseluruhan pengukuran kualiti perlu dilakukan keatas khidmat diberi kepada semua ataupun satu sampel kumpulan sasaran. Oleh itu, hasil setiap khidmat perlu diukur dan direkodkan. Yang lebih penting pemberi khidmat perlu sedar tentang tahap kualiti yang perlu diberikan olehnya dan berusaha sedaya upaya kearah mencapainya.

Hubungkait Pengukuran dengan Pengawalan

PENGAWALAN DAN MAKLUMBALAS

Fungsi Pengawalan

Fungsi pengawalan ialah :

- Memastikan supaya input, proses dan output menepati spesifikasi

- Memeberi maklumbalas supaya proses yang sediada boleh diperbaiki

- Memeberi maklumbalas supaya rekabentuk produk yang lebih baik dicipta pada masa hadapan

Memberi maklumbalas merupakan suatau fungsi penting pengawasan.

Pengawasan Kualiti dan Maklumbalas dalam Sistem Pengeluaran / Pemberian

Untuk melaksanakan pengawalan kualiti input dan proses, suatu keterangan yang terperinci dan teliti mengenai keperluan keperluan kualiti (spesifikasi) wajib ditentukan. Hanya bila kehendak kehendak tersebut dipenuhi barulah pengeluaran atau pemberian perkhidmatan boleh dimulakan. Maklumbalas yang menenunjukkan kemungkinan berlakunya kemerosotan kualiti ketika proses pengeluaran masih lagi berjalan (on-line control) membolehkan pembetulan dibuat sebelum kerosakan berlaku. Audit atau pemeriksaaan produk selepas produk telah siap dikeluarkan (off-line control) hanya bernilai sebagai pemeberi maklumat maklumbalas bagi memperbaiki pengeluaran selanjutnya atau untuk projek dilain masa. Pelanggan luaran merupakan punca maklumbalas yang terpenting tetapi suatu sistem untuk menyalorkan malumbalas antara pembekal dalaman dengan pelanggan dalaman juga perlu diadakan. Kerjasama pengeluar dengan pembekal luaran juga adalah sama penting.

Pengawalan Kualiti dan Maklumbalas untuk Penyediaan Sistem Pengeluaran / Penyampaian Perkhidmatan Baru

Keupayaan menepati spesifikasi boleh ditingkatkan dengan pengawalan yang lebih baik. Pengawlan input dan proses yang rapi membolehkan hasil yang dikeluarkan menjadi lebih seragam dan sentiasa memiliki ciri ciri kualiti yang ditetapkan sambil mengurangkan bilangan produk yang tidak boleh dipakai atau terpaksa dibuat semula.

Suatu ketika dahulu, pengawalan kualiti merupakan mekanisma tunggal untuk menetukan kualiti. Kini, ia dianggap sebagai satu daripada pelbagai unsur unsur teras lain pengurusan kualiti. Perlu dingat bahawa jika pengawalan dan pengukuran kualiti tidak digunakan secara berkesan, ia akan mengakibatkan peningkatan Kos Kualiti kerana belanja yang perlu dikeluarkan untuk memperolehi peralatan mengukur dan kepakaran serta kos tenagakerja untuk melaksana tugas tugas ini.

Rekabentuk yang baik beserta mekanisma pencegahan boleh mengurangkan pergantungan kepada pemeriksaan produk dan audit.

KUALITI HASIL

Keperluan Mengukur Kualiti Hasil

Dalam penyampaian khidmat penjagaan kesihatan, seperti juga dalam perkhidmatan lain, tahap kualiti pada hasillah yang paling dihargai. Kualiti produk terakhir atau hasil perlu diukur atas sebab berikut:

- to know whether the objectives (standards) have been achieved

- to provide comparison with previous and future performance

- to allow comparison with others

- to know the degree of inadequacy or shortcoming

- provide feedback for quality improvement

QUALITY CHARACTERISTICS OF OUTCOME

The desired outcome of patient care differs from disease to disease and from patient to patient. The characteristics that matter most to patients i.e. their Primary needs are:

- Effectiveness

- Adequacy

- Sustainability

- Safety

The above characteristics become the criteria used for distinguishing an acceptable from an unacceptable outcome.

Measurement & Control of Effectiveness

The patient wants their health problem to be resolved. Their expectation is for their illness to be healed or cured. Yet, this is not possible all the time. In health care, “effectiveness” is defined by the most optimal that can be achieved for a given health problem given the natural history of the illness, the stage at which treatment is sought/given and the patient’s inherent capacity to respond to the illness and treatment. Therefore, effectiveness can vary from cure to obtaining relief of symptoms to experiencing comfort.

“to cure sometimes, to relieve often to comfort always” Ambroise Paré (French Surgeon 1510-1590)

Standards of Effectiveness

In most instances (based on experience and research), the expected outcome of a given disease is known. To compare results between providers or institutions or for different periods within the same institution, the outcome of a population of patient is a more appropriate standard to use. This is usually a range because of the variation between patients and in the stage, grade and severity of the disease. The width of this range (degree of variation in the outcome) is dependent on the heterogeneity of the group of patients (the population). When patients are more alike (heterogenous) this range is narrow. The measurement of quality for a population of patients is performed through the activity of Medical audit. (to be discussed in a separate article)

However, it must be remembered, that a population is made up of individuals. Therefore the outcome achieved for each individual must be measured and documented first. More importantly, a conscientious care provider would set the optimal expected outcome (the standard) for each individual patient and strive towards achieving it. This standard is based on a set of specifications (often using a scoring system). The topic of outcome documentation is discussed further in the article on ‘Monitoring, Review, Assessment and Continuity’.

Measurement and Control of Adequacy

Adequacy refers to the completion of all that is necessary to be provided or performed. The comprehensiveness of the service provided is discussed in the article on “Clinical Care Processes and the Total Patient Care Concept”. To measure adequacy, the components of care are itemized when the Care Plan is designed. It is a measure of adherence to plan. At a gross level, control involves making sure that list of tasks planned is carried out. At a finer level, there is a need to ensure that the content of each item in the service (the intermediate products) is sufficient.

The method of control would involve not only the use of checklists to ensure completeness but also determining the adequacy of content of each process. The latter would require observations of processes as they are performed or an interview of the patient/carers. The topic of ‘Care Plan’ is discussed in another article.

Measurement & Control of Sustainability

Sustainability is the guarantee that what has been achieved has a certain degree of permanence.

The degree of permanence is dependent on the nature of the illness and whether recurrence can be prevented or otherwise. This does not necessarily mean the termination of the disease or problem. For diseases such as infection or malignancy, permanence (cure) is achieved if all malignant cells or organisms are eliminated. For chronic illnesses, sustainability of the treatment corresponds to maintenance of the optimal health status. Quality Control is used to asses the care provider’s ability to provide services that enable patients to maintain acceptable level of various physiological, psychological or social parameters, avoid triggering factors and follow conducive life style and habits. Therefore, the measure of sustainability can be:

- the frequency of recurrence

- disease free interval

The care provider need to work towards promoting the persistence of wellness and avoidance of the worsening of health (recurrence, development of complications ). These actions are termed as ‘continuity of care’ and include:

- regular follow up (monitoring, review & reassessment)

- ensuring compliance

Hence, actual and surrogate (representative) measures of sustainability include:

- The duration of absence of symptoms or effects of the disease (the disease free interval)

- Re-admission rates

- Frequency of occurrence of exacerbation (e.g. in Bronchial Asthma or Psoriasis)

- Degree of compliance (through self-reporting by the patient or using indirect measures)

Measures that demonstrate the adherence to plans e.g. compliance to the follow up appointments, performance of review using key tests (such as HbA1c for diabetes) as scheduled, are examples of indicators of quality of process.

Measurement & Control of Safety of the End Product

Safety is more of an issue relating to the process of care rather than outcome. Yet, there are instances when the final effect of treatment may give rise to increased risks to the health or life of the individual. Before providing a certain treatment method, due consideration need to made on risks to the patient’s safety. Specific examples are: leaving an organ donor with only one kidney, giving Warfarin to a patient after replacing a heart valve and putting a patient on life-long immuno-suppressant drug.

QUALITY CONTROL OF PROCESSES

THE NEED TO MEASURE QUALITY OF PROCESSES

The work of providing care is achieved mainly through the performance of procedures (jobs) which are further broken down into processes (tasks). How the processes are to be performed and what equipment is to used and the persons eligible to perform the processes are determined when the service delivery system is designed. In other words, there is a prescribed way of performing processes which needs to be conformed to.

How processes are performed affects all aspects of service delivery operations including:

- Productivity

- Efficiency

- Quality

- Safety

Indeed, efficiency (speed and timeliness) and safety are considered as quality characteristics of a service.

How Processes Transform Input into Output

The conformance of the quality of processes to acceptable standards is determined through two main methods:

- conduct of the process

- evaluation of the characteristics of the intermediate product

At the individual patient level, the quality of processes and the output of the process (intermediate output/outcome) is measured to ensure the following:

- they are performed according to stipulated (design) specifications so that the desired outcome is achieved

- the well-being and safety of the patient while undergoing the process

- the whole experience (physical, psychological and social) is as pleasant, dignified and acceptable as possible

Thus for a patient, each process need to be under constant scrutiny to ensure that each subsequent step proceeds only if the procedure thus far is going according to plan. Like assembly lines the entire process of a service can be stopped and resumed only after adjustments are made to faulty or inadequate input (equipment, instruments, materials, human resource) or the environment made more conducive. In services once given, the final outcome (both the benefits and harm encountered) cannot be undone, reworked or recalled. However there is, in most instances, a window of opportunity to somehow seek a different path, redress the shortcomings, repair some of the damage and recover some of the losses. Control mechanisms of processes or intermediate products such as Progress Review and Re-evaluation can help improve the final outcome. If the treatment as planned proved to be ineffective or inappropriate, the Care Plan may be redesigned. If a defect is discovered, damage control through efforts such as amelioration of side effects and tertiary preventive measures (e.g. rehabilitation) can be done. If there is error of omission, it may not be too late to perform the necessary task. Quality control of the care of an individual patient is more useful if it is prospective rather than retrospective.

However, knowing how a care provider or a service (team, unit, hospital) fare when caring for a group of patients (a population) is also important for the following purposes:

- to enable comparisons to be made

- with others or a benchmark

- with the performance at an earlier period

- to provide feedback for improvement of service delivery systems, processes and product design

Measuring the level of quality of processes in a population is called Statistical Process Control. In healthcare. the main method is Medical Audit.

QUALITY CHARACTERISTICS OF PROCESSES

A process does not stand on its own. Instead, a set of various types of processes make up a procedure. Procedures and processes can be divided based on their purpose and the method used into:

- Technical Process

- Communication

- Cognitive Process

- Data Management Process

- Administrative Process

A procedure is made up of a combination of the above process types. Measurement of quality characteristics may be performed at the procedure or the process level. Each of the types has a different set of quality characteristics. Also quality of process is perceived differently from the point of view of the customer as opposed to the provider.

Measurement & Control of Technical Processes

A technical process is a manual act performed with or without the aid of tools or instruments. It could also be completely mechanized and automated.

Quality characteristics of technical processes valued by customers include:

- Precision

- Efficiency

In health care, patients would like to experience processes that gets the intended output (get it right) with minimal efforts; preferably ‘first time every time’. They would appreciate if it is performed on time and taking the shortest time.

For the care provider, control measures should assist him/her to achieve the intended outcome. Control here means ensuring conformance to the process design i.e. knowing that the procedure or process is performed the way it should be, preventing it from going wrong and correcting any mistakes. Achieving control depends on two factors:

- The desire and ability of the person performing to do it right

- Supervision

Therefore the quality of processes performed is dependent on the knowledge, skills and attitude of the operator (care provider or technician). In healthcare where care providers are constantly learning new tasks supervision and training is the key to ensuring quality. The supervisor can assess and influence the performance of each individual worker.

Measuring conformance requires a clear description of procedures and processes. This is achieved by documenting them as Standard Operating Procedures.

From the perspective of operations management, the manager (or anyone responsible for quality management and system design) would want to know the frequency of conformance to the process for all instances of service delivery. The quality control data would allow for the calculation of frequencies and rates (percentages, proportions). He/she would then be able to gauge:

- the capability of workers to perform processes

- which particular process(es) is poorly performed

- which procedure/process fails to produce the intended outcome

The data made available, would provide feedback to the manager (quality manager, supervisor) and help him/her devise means of improving conformance (usually through training, supervision or motivation.

Through Statistical process control the system designer (technical expert or specialist) evaluates which procedure/process fails to produce the intended outcome. Following that a more detailed study is carried out by:

-

- observing the process as it is being performed,

- studying the outcome of the process (the intermediate outcome)

- obtaining feedback from the worker who performs the process.

In this way the inherent characteristic of the process (as it is practiced) is known and the information is used to improve its design. The following characteristics should be measured:

-

- Effectiveness

- Reproducibility

- Ease of performance

- Efficiency (Optimal use of resources)

Measurement & Control of Communication as a Process

Communication between care providers with each other and with patients is an important aspect of service delivery. It impinges on effectiveness and safety of the final outcome. Good communication puts patients at ease, promote compliance and enhance the whole service experience. They would appreciate communication that is effective, friendly, respectful, adequate and clear. Communication requires the right skill, knowledge and attitude.

Control of the quality communication during the provision of care of an individual patient is difficult. A good method to gauge clarity and adequacy of patient education, briefing and instruction, is to seek a response from the patient whether he/she understands them. In some instances, he/she may be asked to repeat the instruction given.

The measurement of quality of communication provided to a patient population is gauged by through Customer Satisfaction Survey including it as one of the criteria. This is more useful if the survey is conducted for a specific service product.

Productivity, Efficiency and Quality

Systems in operation for Service Delivery

It is also important to ascertain that equipment used is in proper functioning order and staff with appropriate knowledge and skills are assigned to perform the processes. The atmosphere / environment also need to be controlled. Therefore, quality control is more beneficial if it is prospective (preventive) rather than retrospective (reactive) in approach.